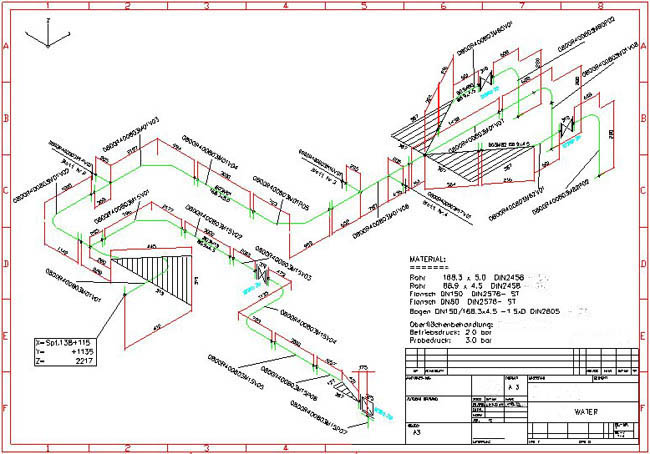

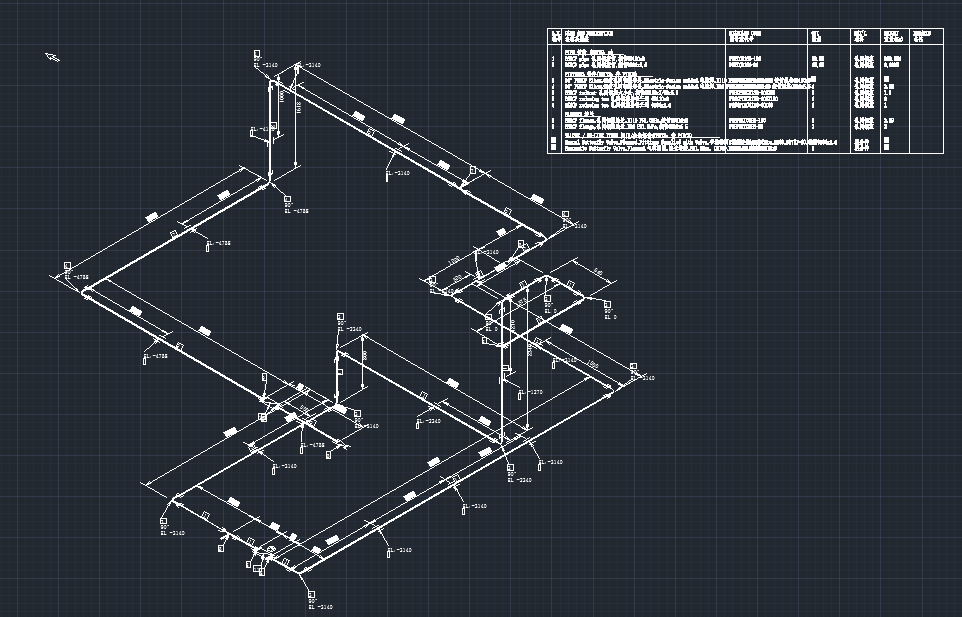

This is to avoid any confusion caused by nodes being placed over the top of other nodes or pipes. When clicking the ISO Mode On/Off Toggle button to transpose from isometric view to a 'flattened' standard view, any vertical lines from the isometric view will be drawn at 45 degrees. Selecting either of these options will change the display of all tanks and end pressure on the isometric view. The drawing menu provides options to display an ‘Isometric tank view from the left’ or to display an ‘Isometric tank view from the right’. Tanks and end-pressure nodes will also be displayed in the isometric plane. When the isometric drawing mode has been selected Pipe Flow Expert will show fittings, valves, components, control valves and pumps in the isometric plane which follows the associated pipe direction. Users can easily switch between these using the ISO Mode On/Off Toggle button. Pipe Flow Expert has two drawing modes, standard (‘flattened’) view and isometric view. It is very difficult to find such information in the preliminary MTO.Yes. This software gives the actual length of the pipes and the number of elbows used in the piping system. Secondary MTO is prepared with the help of PDMS/PMS/E3D by extracting the isometric from the ISO-draft module. This is prepared with the help of the material control group. It must be done early enough to ensure that the procurement of the piping materials could fit the project schedule. It may include the piping design done on 3D modeling software or 2D software.

When there is significant progress on the piping design, The secondary MTO is prepared.

On the MTO sheet, enter the line number, line class, and line size.Identify the numbers of lines, line classes/specs, and the line size from the P&ID.PMS (Piping Material Specification) Steps for Preliminary MTO Preparation.Bidding of the material/ Request for quotation (RFQ) Documents required for Preliminary MTO are.There are two reasons for preparing the preliminary MTO:

0 kommentar(er)

0 kommentar(er)